Evaporative cooling is the basic of mostly all refrigeration technology that involve a phase change in refrigerant.

The Evaporative technology is used in Hot and dry areas. In these areas it is more effective and cost efficient than the air conditioners. But in humid areas, Evaporative cooling does not bring thermal comfort.

Thermal comfort is a state where our body feel good with respect to temperature of surrounding.

Working principle Evaporative cooling: For Moist air:

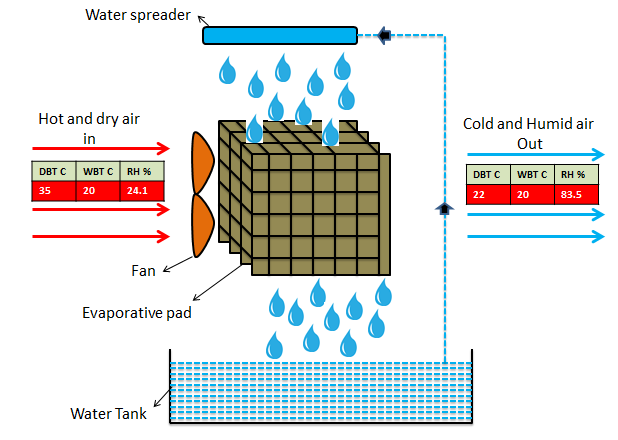

When hot and dry air pass through an evaporative pad (a wet pad, with same water quantity always during evaporative process), It take some water(wet vapor form) from pad and the heat require to evaporate water is taken from water itself. As latent heat is almost 100 times the sensible heat for water, So a small portion of water will evaporate, resulting in overall reduction of temperature of water and air leaving the air and water at wet bulb temperature of entering air. (refer to figure)

The Evaporative technology is used in Hot and dry areas. In these areas it is more effective and cost efficient than the air conditioners. But in humid areas, Evaporative cooling does not bring thermal comfort.

Thermal comfort is a state where our body feel good with respect to temperature of surrounding.

Working principle Evaporative cooling: For Moist air:

When hot and dry air pass through an evaporative pad (a wet pad, with same water quantity always during evaporative process), It take some water(wet vapor form) from pad and the heat require to evaporate water is taken from water itself. As latent heat is almost 100 times the sensible heat for water, So a small portion of water will evaporate, resulting in overall reduction of temperature of water and air leaving the air and water at wet bulb temperature of entering air. (refer to figure)

For Example let ambient air is at 35 DBT and 20 WBT with RH of 24.1% having enthalpy of 56.84kJ/kg. Cp and density of ambient air is 1.021 kJ/kgK and 1.14 kg/m3 respectively. Amount of water in ambinet air is 8.44 g per kg of dry air.

Assume CFM of 400 for Fan. and latent heat of vaporization of water is 2260 kJ/kg.

By using equation m*Cp*dT, the total heat transfer 2856.77 W and air exit at 22 DBT and 20 WBT (considering irreversible process) with water amount in air increase to 13.84 g per kg of dry air.

So amount of water added per sec to air is 0.58 gm. By using the latent heat vaporization of water multiply to water amount per second added in air, the actual heat transfer in the process is 2628.64 W.

The loss of 2856.77-2628.64= 228.14 W or 8% of total heat transfer is due to the heat gain by evaporative pad while in contact with ambient. Ideally the dry bulb temperature of exit air from the evaporative pad will be equal to Wet bulb temperature of air.

If the above set up will run continuously, around 4.19 liters of water will evaporate every hours.

Both the heat transfer ideally should be same as per process of evaporative cooling(Adiabatically: No heat supplied or rejected from outside).

Working principle Evaporative cooling: For Capillary tube in Refrigeration:

The above said principle is applicable for capillary tubes as well. In capillary, pressure of refrigerant reduces so that some refrigerant converted in to vapor by taking the latent heat from refrigerant itself resulting in reducing the temperature of refrigerant sensibly. Larger the temperature difference, more the quality of refrigerant at capillary outlet.

Using equation m*Cp*dT the total heat transfer can be calculated. Also by multiplication of mass flow rate and latent heat of refrigerant at evaporator in temperatrue and quality at evaporator inlet the heat transfer can also be calcualted. Both the heat transfer ideally should be same as per process of evaporative cooling(Adiabatically: No heat supplied or rejected from outside)

Comments

Post a Comment